We present India’s 1st Refrigerant Automatic

System similar to other processes e.g.

Nitrogen, Oxygen, Air, etc.

Automatic system

We present India’s 1st Refrigerant Automatic System similar to other process e.g. Nitrogen, Oxygen, Air etc.

Market Competency

With this ISO Tank (Refrigerant system) will overcome traditional method (Tonner) eliminate the refrigerant left over saves refrigerant by 10%

Exponential rise in refrigerant cost by 76%

By adapting this system will detract the manufacturing cost of air-conditioning unit & environment consiousness

Technical Data Sheet

|

Design |

SMPV (U) Rules 2016 |

|---|---|

|

Refrigerant Type |

R-12, R-22,R-32, R410a, R134a, Co2 & Ammonia |

|

System Capacity |

10 MT to 80 MT |

|

Grade |

Fully Automatic |

|

Output Flow Rate |

0.8 MT to 3.2 MT @ 4.5 Mpa |

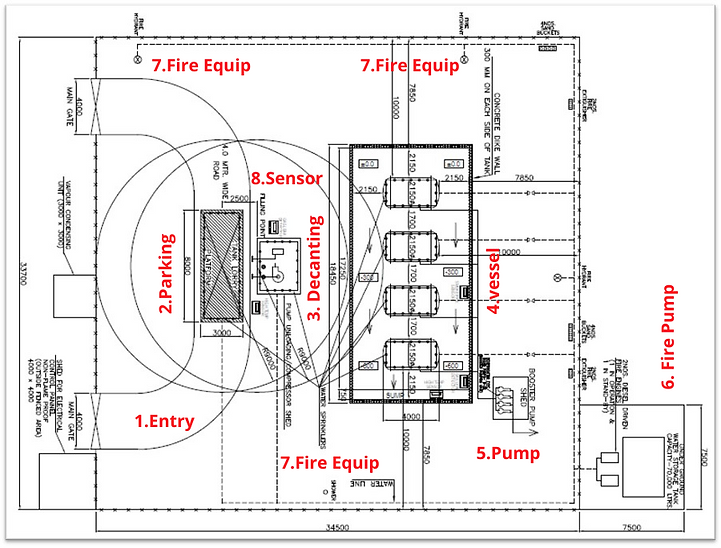

Facilities & Function

- Entry Gate

- Decanting Facility

- Booster Pump

- Fire Fighting Equipment

- Vehicle Parking Stand

- Storage Vessel

- Fire Water Pump

- Safety Alarm Equipment

Key Benefits

We have decided our target ready to launch the refrigerant system.

Refrigerant Booster Pump

We present India’s First Refrigerant charging Booster Pump having world’s level of Features

Refrigerant Booster Pump

Technical Data Sheet

|

Design |

PLC Integrated Reciprocating Pump |

|---|---|

|

Refrigerant Type |

R-12, R-22,R-32, R410a, R134a, Co2 & Ammonia |

|

Flow Rate |

50 to 600 kg./hr. |

|

Output Pressure |

0.5 to 8 Mpa |

|

Power System |

Inverter Motor |

|

Features |

Safety Valve with Poka-yoke Alarm |

- Automatic Tonner change-over if cylinder liquid gets empty.

- Timer Base Alarm notification for operator comfortless.

- PLC integrated to deal with numerous logics & interface easily.

- Wide Range of Settable Output Pressure as per customer production line.

- Integrated with Safety Valve to tackle abnormal conditions.

- Motor-based pump eliminates issues with a pneumatic cylinder.

- 3 times cheaper than import Booster Pump.

Mass Flow Meter Error Alarm Solution

- During Summer Season, Refrigerant phase becomes unsaturated, Refrigerant measuring equipment (Mass Flow Meter) does not recognize to measure the flow rate. It generates alarm of Mass Flow Meter results in to stoppage of Production line.

- As a solution we provide India’s best practical adopted by many OEM. Refrigerant is highly sensitive w.r.t. temperature. We have specially design a machine which sensibly works on refrigerant properties & will never cause any production line loss.